Modular house with super technology. Modular house projects

Some believe that a modular house is exclusively a building for temporary residence without utilities and other comfortable conditions. In fact, it is no less cozy and equipped than a house built according to the classical scheme. Modular sections are made of high quality materials, so the structure will serve the owner for many years. They can be built in areas with watery soil, seismic hazard, that is, where it is impossible to erect a capital building. Turnkey modular houses are equipped with furniture, have interior decoration and are perfect for permanent residence.

Typical and individual projects of modular houses

MINIDOM company brings to your attention its projects of turnkey modular houses with prices divided into:

1. . They are very affordable and quick to execute, as they will be erected according to a template and assembled in ready-made modules. If you want to get a proven, high-quality assembled modular house in a short time - choose among them.

2.. This way is for those who want to buy a modular house according to their own, original, non-standard wishes. To do this, our specialists will create a new project from scratch solely according to your requirements. We are able to fulfill an order of any complexity!

For the optimal choice, we have laid out turnkey projects of modular houses with specific descriptions, detailed photos, layout and a list of possible furniture. Our specialists have been engaged in prefabricated buildings for over 10 years, they know all the nuances for high-quality construction of a modular house for year-round living. We have our own production and over 100 completed projects. Plus our houses can be transported on public roads without special permission. If you are looking for a responsible and trusted performer - choose MINIDOM!

Why are modular houses so beneficial?

Previously, modular construction involved only the construction of temporary trailers, storage rooms, storage rooms and retail outlets. But having appreciated the advantages of the technology, they began to actively use it for the construction of inexpensive residential buildings. The main advantages of turnkey modular houses:- Mobility... You can always disassemble the house into modules, transport it and assemble it in a new place. Thanks to the light weight of the sections, this does not require heavy equipment.

- Availability... The price of a turnkey modular house for permanent residence will be several times cheaper than the cost of building a traditional real estate.

- Fast assembly... If an ordinary house is being built sometimes for years, then here the time period for the commissioning of an object is calculated in weeks, and sometimes in days. During construction, you can do without a foundation.

- Resistant to any weather... The modules are made of high-tech materials, so the structure does not lose heat in winter and does not heat up in summer.

- All stages from "A" to "Z": construction, finishing, furnishing. Choosing a turnkey modular house project, you get a dwelling completely ready for year-round living.

For the first time, they started talking about modular houses in the United States in the post-war period, when the question of providing housing to people became the most pressing issue. Despite the fact that at first this type of housing was meant as temporary, after a short time, prefabricated buildings began to be used as places for permanent residence. The technology of modular construction began to spread rapidly all over the world - many people liked comfortable and mobile prefabricated houses, due to a whole range of advantages.

The houses were assembled from specially prepared modules, each of which had its own purpose. The components assembled together made up a dwelling in which one could live comfortably, as in a familiar house, erected using capital construction technology. Over the past 100 years, prefabricated modular houses have not lost their relevance at all, and on the contrary - every year such buildings are becoming more and more in demand, including in our country.

Modular house Rodnik series

We have developed a typical modular house of the Rodnik series, which is based on modified Universal modules. A well-thought-out design of the frame allows you to deliver such a house with turnkey interior decoration in just 1 month. The house is designed for use in a wide variety of climatic conditions in the temperature range from -40 ℃ to + 40 ℃.

from 34,900 rubles / sq.m.

base price for your home

House layout Rodnik

- At the base of the house - metal frame

- Supplied in bags, assembled on site

- Walls - ready-made panels with electrical preparation

- High flexibility in choosing layouts

- High installation speed

Advantages of modular houses

Modular houses have become in demand as a place for year-round living due to a number of advantages:

- The main advantage of houses made of metal structures is their quick construction. Construction is carried out on a parallel basis, i.e. all work is carried out simultaneously on 2 construction sites: at the first site and the foundation are prepared, as well as the connection of the necessary communications is carried out, at the second, modules are directly manufactured, in accordance with the wishes of the customer.

- Each module is made in accordance with all modern production standards, when assembled, all blocks are compatible with each other and accurately sized to ensure the quality and reliability of the houses made from them.

- For the production of modules, a wide selection of all kinds of materials is provided, each of which allows you to easily solve problems of simplicity, comfort and warmth in the room.

- Low price for 1 sq. m. of modular housing, which is almost several times lower than in capital construction, makes it possible to solve the problem of choosing a place for permanent residence with minimal costs.

House interior of the Rodnik series

Stages of manufacturing a modular house at a factory

The process of manufacturing a dwelling from modules can be conditionally divided into several stages. At the first stage, the customer provides the project of the future house to the manufacturer. When drawing up a plan, it is important to take into account both the location of rooms, doors and windows, and various options for connecting utilities.

The next stage involves the preparation of documentation for an individual construction plan, calculation of estimates, as well as the determination of building materials for finishing work. The foundation is calculated taking into account all the features of the project, it often does not require large material costs and a lot of time for its installation, since the construction is carried out on the basis of light screw piles.

And the third stage is the coordination and approval of the project and the start of construction work. The manufacturer issues a package of all required documentation, guarantees and certificates for each module separately. As a result, it takes on average up to 2 weeks to create a standard house from modules.

Development of modular construction in Russia

According to forecasts, modular houses for year-round living in our country will soon become even more in demand - already today there is a high consumer demand for houses built using this technology. When building them, 3 important principles are taken into account - efficiency, speed and ease of construction. Modular blocks contain only environmentally friendly components, so living in such buildings is not only comfortable, but also safe. There are a variety of configurations of houses made of metal structures, and, no less important, it is possible to order a different area in the module.

Panels in such houses are made in the form of a multi-layer sandwich (2 layers of a cement-layered slab, 2 layers of steam insulation and a layer of basalt insulation), due to which they received the appropriate name - sandwich panels. A warm modular house in terms of its thermal insulation properties significantly surpasses brick masonry. Its walls are characterized by a high quality coefficient, and insulation materials are not subject to atmospheric influences (moisture, direct sunlight, etc.). In addition, the entire production process is carried out under the close supervision of the plant representatives.

The interior decoration of the house is carried out in accordance with the customer's requirements: fiberboard, chipboard, galvanized iron, etc. are usually used. When designing, it is important to take into account the purpose of the room and its useful area, based on this, determining the dimensions of the modules and the number of storeys of the building. To ensure fire protection, the walls of the modular house are treated with a special refractory mortar. Such premises, in addition to the previously listed technical features, also have additional advantages, including:

- assembly of modules can be carried out at any time of the year and in any weather;

- due to the mobility of housing, it can be easily disassembled and transported to a new location at any time;

- depending on the customer's requirements, the number of storeys of the house can also be increased, if necessary, up to the 3rd floor;

- internal and external finishing of the module can be ordered at the factory;

- many building parameters of a modular building are several times higher than the parameters of capital buildings;

- thanks to high-quality insulation, energy consumption for heating is significantly reduced.

Prices for the construction of modular houses

These prices are basic and do not include foundations, engineering and furniture. The option of supplying a house with a complete set is possible.

The advantages of modular houses are that factory production provides high quality installation and finishing works, and reduces the cost per square meter. The record speed of construction of a completely ready-to-use building attracts customers from among industrial and travel companies. Interest in them is also growing among development companies engaged in the business of building and selling land plots.

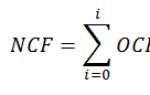

The fall in the purchasing power of the population, according to realtors, has increased the demand for economy class housing. According to the Miel group of companies, in 2015 - 2016 the number of those wishing to build a house worth up to 1 million rubles, and an area of up to 100 sq. m, increased by 63%. The least costly in construction are pre-fabricated buildings, which are widespread in America and Europe. When considering a modular home business, you need to evaluate several components:

- how its organization differs from other types of construction;

- how much investment is required to start production;

- determine the circle of customers and the demand in the region;

- to analyze the existing enterprises in this area;

- evaluate the profitability of starting a franchise business.

According to the Minister of Construction Mikhail Men, in 2015, the Chinese company Zhoda approached him with a proposal to build low-rise modular houses in Russia. The German Knauf is setting up a joint venture with the Russian Sveza Group, intending to invest about 7 million euros in production. Her calculations showed that the demand for such houses will grow, the investment will pay off.

The essence of the business model and organization

Two types of prefabricated buildings are widespread in the world: frame and volume-modular structures. The construction technology of the former provides for the construction of a frame made of metal piles or wood, the assembly of which on site requires a good qualification of the builders. Modular blocks are completely manufactured at the factory, which leads to a record speed of installation of a ready-made house: 2 - 3 days. Compared to frame structures, they have significant advantages:

- increased strength and longer service life;

- the possibility of equipping with internal communications;

- production of interior decoration in the factory;

- mobility - they are easy to move to another place;

- the ability to add blocks at any time;

- lack of construction waste, preservation of the landscape.

The only drawback is some monotony, which limits the possibilities of architectural delights. Nevertheless, geometric shapes designed with the help of professional designers can also look very interesting (Fig. 1).

Cost of 1 sq. m of housing produced using this technology in factory workshops is significantly lower than market prices for apartments and houses built in the traditional way. It ranges from 19 to 25 thousand rubles, and strongly depends on a set of additional options: autonomous heating, electrification, alarm and so on. Individual blocks differ in shape, sizes vary widely.

The ideal business organization scheme (Fig. 2) provides for the creation of an integrated group of companies on the basis of contractual relations, and includes:

- a plant for the production of volumetric modular buildings (OMZ);

- a network of regional dealerships for promotion;

- construction organizations - installation and development of the territory;

- management company for organization and management (MC).

The central link in the system is the RMZ plant. It is being built or (more often) adapted by reconstructing part of the existing workshops. This is the most costly part that requires large investments (more on that below). If the first option is used, the management company retains 100% of the equity participation, while retaining control over production and sales. The products of the plant are separate functional blocks manufactured by conveyor belt method. Depending on the order, a building with specified parameters and internal filling is formed from them.

The management company performs many functions:

- determines the list of required equipment, materials;

- draws up an estimate indicating funding sources;

- designs workshops, production lines for equipment;

- develops (acquires) technological documentation;

- organizes start-up and commissioning works, reaching the design capacity;

- plans production, staffing, personnel training.

The Management Company is also involved in coordinating the work of dealerships, transporting finished OMZs, servicing and advertising. With an integrated approach, a developer who has a leased or owned land plot is engaged in the development and approval of a general development plan, laying of engineering communications. Individual customers indicate the place of installation of the house on their own.

Financial investment and return on investment

Investments in the production of modular blocks are considerable if you start from scratch. Reorienting production, if there is already available space, a partial set of equipment is much cheaper and easier. In general, financial investments are required:

- to develop a business plan adapted to its capabilities;

- for the purchase of technology, organization documentation, equipment;

- for the development of a 3D project for work and demonstration;

- for an advertising company, including the creation of an Internet site;

- for company registration and preparation of Constituent documents;

- for the production of a prototype and exhibition sample.

Let's give as an example an approximate calculation of the organization of production of hotel-type buildings, placed on the site of the "Investors' Club".

Products - blocks S = 32 sq.m. three types: economy class (5 rooms of 6 sq.m.), a module for 2 rooms with a terrace, and a single suite with a bathroom. The volume of the issue is 20 modules per month. The approximate amount of investment will be:

- arrangement of a factory conveyor line, rent of premises, advertising - 5,000,000 rubles;

- purchase of a 2-week stock of materials and components - 4,000,000 million rubles;

- the planned payback period of the project is 1.5 months with a margin of 350,000 rubles.

In the field of prefabricated buildings, there are no uniform standards, and a huge number of different technologies. House kits are folded like a Lego constructor from separate blocks and elements. Versatility is ensured by the standardization of walls, corners, tees, floors. Metal and wooden frames are used as a basis, but all-metal block containers are considered the most reliable. Volume-modular structures of this type are in demand in the construction of industrial buildings. The share of materials in the cost of production is approximately 60 - 70%.

Sales prospects and consumers

It cannot be said that the construction of cheap modular-frame buildings is an absolutely new idea for our country. However, its development was hampered by the lack of quality supply on the market and the skeptical attitude of the Russian consumer. The situation in this regard is changing rapidly. Customers of prefabricated buildings can be roughly divided into four categories.

- Large construction,gas and oil companies , exploration enterprises. They massively purchase products for the arrangement of temporary shift camps. They are ordered by Rosneft, Transstroy, French Schlumberger and many others. For them, various objects are mounted: change houses, dormitories, canteens, industrial buildings.

- Recreational tourism industry. Modular houses are widely used for organizing tourist camps, recreation centers, summer camps, hotels, medical centers. They are suitable for the construction of sports complexes: swimming pools, gyms. Thus, the Vologda "Plant of Building Structures and Road Machines" completed an order for the production of modular houses for the Sochi Olympics and the Asia-Pacific Summit for 14 villages with a total area of 111,000 sq. M.

- Trade, transport, logistics companies. Block containers are ordered for the organization of trade pavilions, warehouses, small cafes, various household premises. On their basis, garages, car services, security posts are equipped.

- Private and centralized residential construction. Increasingly, modular houses are ordered for the arrangement of a summer cottage, both by individual clients and by developers implementing large projects. They are attracted by the low cost, and the short term for obtaining habitable housing. So, in the Moscow region, a whole cottage village "Gorki 90-18" of modular houses with an area of 30 - 75 sq.m. has been erected.

An example of a realized production

The organizers of the tourist route to one of the uninhabited islands in the Maldives have ordered a modular house for the caretaker in the Russian company Uneeco (Moscow, Skolkovo). Its founder is a former lawyer Pavel Bobkov, the case was started in 2013. It was invested 16 million rubles (3 million borrowed). About a quarter of the investment went to the organization of the production line at the Tver plant, 2.5 million rubles. - for the development of the project.

The company produces expensive products of the elite class - fully finished ready-made eco-houses with autonomous communications: heating with solar panels and a pellet fireplace, water supply, electrification, and sewerage systems (Fig. 3). Thus, the Rassvet development group acquired a 106 sq.m. building for an office in one of the villages. for 3.6 million rubles.

Manufacturers initially relied on a private buyer, but the cost for the majority turned out to be unaffordable. Suddenly, customers appeared from the other side: travel companies, the Caucasian Reserve, a construction and investment company from Lake Baikal (ordered 10 houses). As a result, Uneeco shifted its focus to industry exhibitions and expects to sell comfortable mobile cabins to gas and oil workers.

Modular building franchises

As noted above, almost every manufacturer develops its own technology for the production of OMZ. Foreign projects are being adapted to Russian conditions, modernized to use domestic materials. At this stage, you can save money if you start a franchise business. There are such offers on the market; as an example, we cite two of them.

1 "Double House"

Lump-sum payment - 450,000 rubles

Royalty - 5%.

The Moscow company has been producing all-season modular houses since 2013. The range includes 12 models ranging from 26 to 130 sq. m., costing from 990 thousand to 4.6 million rubles. Representative offices are located in St. Petersburg, Kazan, Voronezh. They are looking for partners in the Southern Federal District, Crimea, Siberia. Franchisee requirements:

- the area of the warm industrial premises - from 1,000 sq. m .;

- own (rented) warehouse for materials and components;

- the minimum number of employees is from 5 people.

Experience in working with wooden and engineering structures is required, the partner purchases equipment, materials on his own. The franchisor provides technological documentation, trains personnel, and consults.

2 "Kuban Modular House" (KMD)

Investments - 2,500 - 3,500 million rubles;

Lump-sum contribution - 750,000 rubles;

Royalty - RUB 25,000;

The payback period is 1 year.

The Krasnodar company has been operating since 2010, and since 2015 has launched a franchise offer. Has developed its own patented technology, which does not require large investments in the reconstruction of the existing production.

Partner requirements:

- production area (not necessarily heated) - from 600 sq. m .;

- equipment crane-beam from 3 t (l / c);

- technological line maintenance - 22 people.

The franchisor transfers the rights to use the Trademark and the patent, helps to install and debug the line, transfers technical documentation and supply contracts. Can help to include financing in the State Program.

Summary

Real estate experts predict an increase in demand for modular buildings in the next 3 to 5 years. The main consumers of the products will still remain legal entities: companies and entrepreneurs, but among individual developers, interest in such structures is also growing.

But in order to fully enjoy the positive properties of such buildings, you must entrust the difficult work to our professionals. After all, we have been working in the field of manufacturing and construction of turnkey modular houses since 2004. Over the long period of our organization's activity, we have successfully implemented more than 3,000 projects of varying degrees of complexity. We managed to accumulate rich experience and gain well-deserved popularity among our clients. Therefore, they trust us and advise us to their friends, colleagues and relatives.

Peculiarities

The technology of modular housing construction is widely developed both in private construction (small country, country and garden houses) and in the commercial sphere (trade pavilions, warehouses). The base of the frame is made of metal or wood, and the walls are sheathed with block house, siding, pseudo-timber, OSB or chipboard panels. The thickness of the walls depends on the climatic zone. In regions with severe frost, the depth should exceed 400 mm. In regions with a non-sever, warm climate, 100 mm will be enough. A ready-made modular house is being installed on a strip, block or columnar foundation. If the building is planned to be two-story, then the structure is facilitated, and the first floor is made capital, and the second already according to the attic technology.

Advantages of modular housing construction

Recently, the demand for the construction of modular houses has grown rapidly and there are good reasons for this:

light weight of buildings;

speed of construction;

aesthetic appearance;

durability of operation;

good sound and heat insulation qualities.

The choice in favor of our construction company is obvious

We are professionals in the field of manufacturing structures and building prefabricated houses, because we employ only experienced and well-equipped craftsmen, for whom there are no impossible tasks. They successfully implement innovative developments in their activities, applying them in practice. And the use of effective tools and equipment, reliable and environmentally friendly materials can significantly improve the quality of work and reduce the assembly time for modular houses.

We provide the best prices for modular homes. All this is due to the clear optimization of all working and costly processes: our own production of the main sections, full compliance with manufacturing and assembly technologies, purchasing everything you need at wholesale prices from trusted suppliers, and more.

Our services for the construction of modular houses include:

planning on the site, arrangement of the foundation;

installation of the base of the frame and sections of the structure;

installation of a roof, drainage system;

laying of communication routes;

fixing insulation, vapor barrier;

laying of logs, flooring, installation of ceilings;

mounting of windows and doors;

interior and exterior decoration and more.

We competently distribute the entire sequence of processes:

1. we accept an application for the manufacture and assembly of a modular house and agree on some of the nuances (the volume of work carried out, the number of storeys of the building, the materials used and other special preferences of the customer);

2. we carry out measurements and study the soil of the site, draw up and approve the estimate and design documentation, sign a bilateral agreement;

3. we purchase all the necessary materials, manufacture modular sections and deliver to the site;

4. we carry out the installation of a turnkey modular house, starting with planning on the site, arranging the foundation and ending with the assembly of structures, interior and exterior decoration;

5. we hand over the finished housing to the customer with the signing of the acceptance certificate, the issuance of technical documentation with the specified warranty periods.

Our professionals are waiting for your applications!

Want to calculate the cost of a modular home, learn about the timing of production and assembly, order a service? Everything is extremely simple with us! You just need to contact the manager on the specified, he will promptly conduct a detailed consultation, answer all your questions and accept the order. And our highly qualified specialists will qualitatively assemble a modular structure of any complexity, both according to a standard and according to an individual project in the shortest possible time.